What I’m calling “jitter” is unwanted rapid small movements of the video image vertically and horizontally caused by the mechanical processes of recording to and reproducing from film.

By scanning an area of the kine film frame beyond the edges of the video raster, one can get some insights into the sources of jitter.

Jitter on the Spirit Datacine

The Spirit Datacine seems to be particularly susceptible to jitter. It scans the film while it is moving using a “line scanner” and attempts to detect the location of each frame by sensing the position of the sprocket holes. This mechanical sprocket hole detection is not perfect and small positional errors can occur in the direction of film motion. This is one cause of vertical jitter.

Horizontal registration of the film is also not perfect — this contributes to horizontal jitter.

Jitter on the ScanStation

One reel was scanned on a Lasergraphics ScanStation which does digital registration of the film sprocket holes. A small piece of the sprocket hole above and below each frame is visible on this scan and these sprocket holes remain rock steady — there is no movement at all. This scanner yields a more stable result with less jitter than the Spirit.

However, there is still visible jitter in the scans.

This means that the image recorded on the film is not stable relative to the sprocket holes. Why might that be?

Other Sources of Jitter

The original camera in which the film was exposed is also a mechanical device which needs to move the film rapidly between exposing each frame and then stop the film moving and hold it still while the frame is exposed. An earlier blog post quoted former GTV9 engineer Ian Douglas as saying:

“The biggest problem was the mechanical transport of the film … the large accelerations involved set up vibrations which caused fatigue fractures in the lightly built metal parts. During exposure the film was held stationary by a vacuum pump system.”

Ensuring that each film frame is precisely positioned in the camera gate is once again a mechanical process which cannot be perfect. The presence of “accelerations and vibrations” would only have made this more difficult. Another source of small random positional errors.

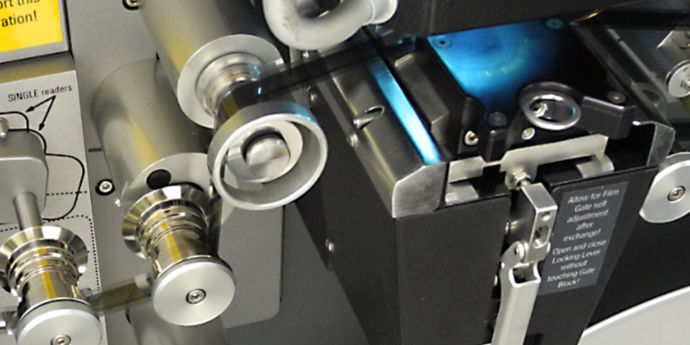

Then there is the entire mechanical arrangement of the GPL film recorder. Repeated here is the photo reproduced in the earlier blog post:

The camera was mounted on a metal chassis, facing the CRT screen which was mounted on the same chassis. Mechanical vibration from the camera transport mechanism, the vacuum system, fans, etc. would likely have resulted in vibrations travelling through this entire structure and causing subtle relative movements of the camera relative to the CRT tube. These include horizontal and vertical movement as well as small rotations of the video image (rotational jitter).

All these factors would have caused subtle frame-to-frame movement of the video raster relative to the sprocket holes, which is why even on a scanner which does perfect registration of the sprocket holes, we still see jitter.

Any attempt at stabilising the image and removing the jitter will need to work with the recorded video raster, not with the sprocket holes.

We will come to the question of stabilisation in more detail in a future blog post.